Lost wax casting cnc machining high temperature alloy turbo discs and turbo impeller for train auto parts.lost wax casting process / soluble glass casting process / silicasol casting process/ die casting process /sand casting process /

| Quantity (pieces) | 1 - 1000 | > 1000 |

| Lead time (days) | 30 | To be negotiated |

Product | Lost wax casting cnc machining high temperature alloy turbo discs and turbo impeller for train auto parts |

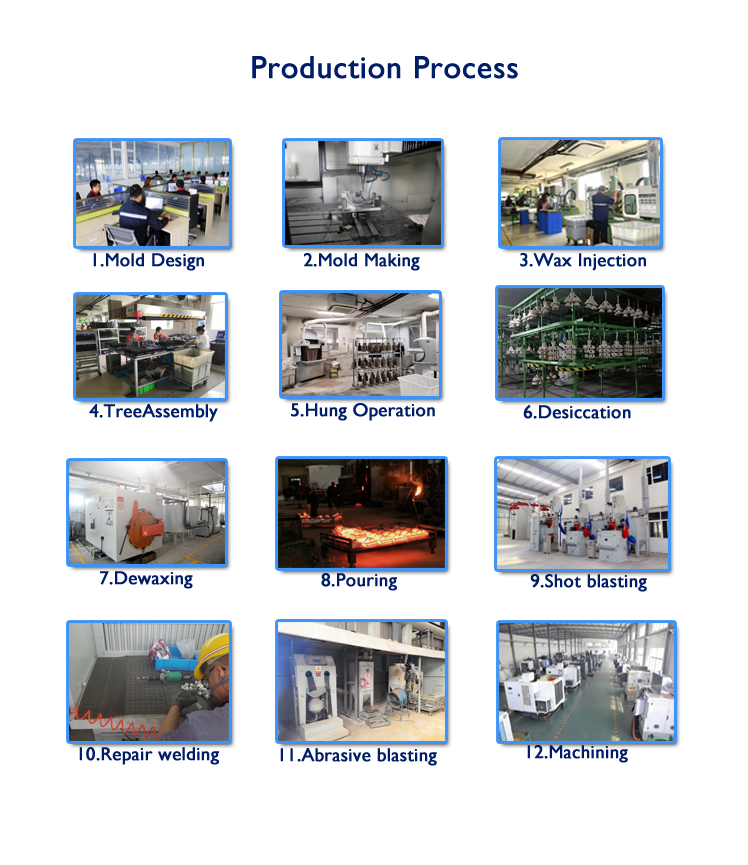

Process Technology | lost wax casting process / soluble glass casting process / silicasol casting process/ die casting process /sand casting process / + Precision CNC Machining + Surface Treatment |

Material we can cast | (1)grey iron, ductile iron , pig iron |

(2)carbon steel, stainless steel, alloy steel | |

(3)Heat resistant Superalloy | |

(4)aluminum ,copper, brass, bronze etc | |

Size | Customized as customer's drawings |

Weight Range | 0.02-50 KGS |

MOQ | 1-2 Pieces |

Tolerance | ±0.02mm |

Surface Treatment | Heat Treatment, Polishing, Plating, Machining, Anodizing, shot, sand blasting, zinc plated, oxide, galvanized etc. |

Testing | Three coordinate measurement machine for testing. |

Certification | ISO9001:2008 |

Standard | ISO , DIN, AISI, ASTM, BS, JIS, etc. |

Hengke Casting Ltd is here to help with all kinds of practical packaging needs. Lost wax casting cnc machining high temperature alloy turbo discs and turbo impeller for train auto parts by Hongdu Paper are sturdy enough and never damage the contents during transit. It’s very popular in our domestic market.

If you are looking for Lost wax casting cnc machining high temperature alloy turbo discs and turbo impeller for train auto parts in China, you are in the right place.Hengke Casting is one of the most famous factory for Lost wax casting cnc machining high temperature alloy turbo discs and turbo impeller for train auto parts.